Can You Weld With Oxy Acetylene

Can You Weld With Oxy Acetylene. Most operators don't find this a. It combines oxygen and acetylene gases to form a superheated flame that melts and joins two pieces of metal.

OxyAcetylene Welding 101 Hot Rod Network from www.hotrod.com

OxyAcetylene Welding 101 Hot Rod Network from www.hotrod.comHow thick can you weld with oxy acetylene? Make sure there are no combustible chemicals or materials in the area where you are going to use welding oxygen. What is a oxy acetylene regulator and how to set it?

The only real downside to using oxy/propane is that it can't be used for actual welding. I have been doing it for over 35 years.

Thinner stick electrodes can also be used without flux. Later i bought some of his product.

A neutral flame setting which comprises 50 percent oxygen and 50 percent acetylene is ideal for welding. Thinner stick electrodes can also be used without flux.

It is not difficult to oxyacetylene weld stainless steel. Gas welding is more practical on thinner metal that coat hanger would be about correct diameter filler but not best filler alloy.

Only operational difference is it will take slightly longer to get the steel up to cutting temperature before you activate the cutting oxygen. It combines oxygen and acetylene gases to form a superheated flame that melts and joins two pieces of metal.

Other welding techniques that are effective for aluminum include tig (tungsten inert gas) welding and mig (metal inert gas) welding. Progress the weld with a steady torch, letting the weld grow on its own, and draw the torch off slowly when finished.

Gas welding was developed by edmond fouché and charles picard in 1903, and by 1906, it has become one of the standard ways to fabricate metals ( 1 ). You can use the tank to weld aluminum metal.

Most operators don't find this a. Gas welding thicker metal can quickly use a lot of gas, making it expensive and slow.

Because steel melts at a temperature above 1,500 deg.c, the mixture of oxygen and acetylene is used as it is the only gas combination with enough heat to weld steel. When you are going to refill the welding oxygen cylinder, you will be asked to state the purpose of the oxygen.

Filler should be kept on the outer edge of the weld letting be 'drawn in'. Gas welding thicker metal can quickly use a lot of gas, making it expensive and slow.

This was before i owned a tig welder, i was impressed. Because steel melts at a temperature above 1,500 deg.c, the mixture of oxygen and acetylene is used as it is the only gas combination with enough heat to weld steel.

He scrubbed it with sandpaper, and picked up an oxy acetylene torch. How thick can you weld with oxy acetylene?

I've heard there are people able to weld al with acetylene. Make sure there are no combustible chemicals or materials in the area where you are going to use welding oxygen.

Most operators don't find this a. Thinner stick electrodes can also be used without flux.

The only real downside to using oxy/propane is that it can't be used for actual welding. It is useful specifically at places.

However, acetylene is not stable for underwater welding or cutting. Because steel melts at a temperature above 1,500 deg.c, the mixture of oxygen and acetylene is used as it is the only gas combination with enough heat to weld steel.

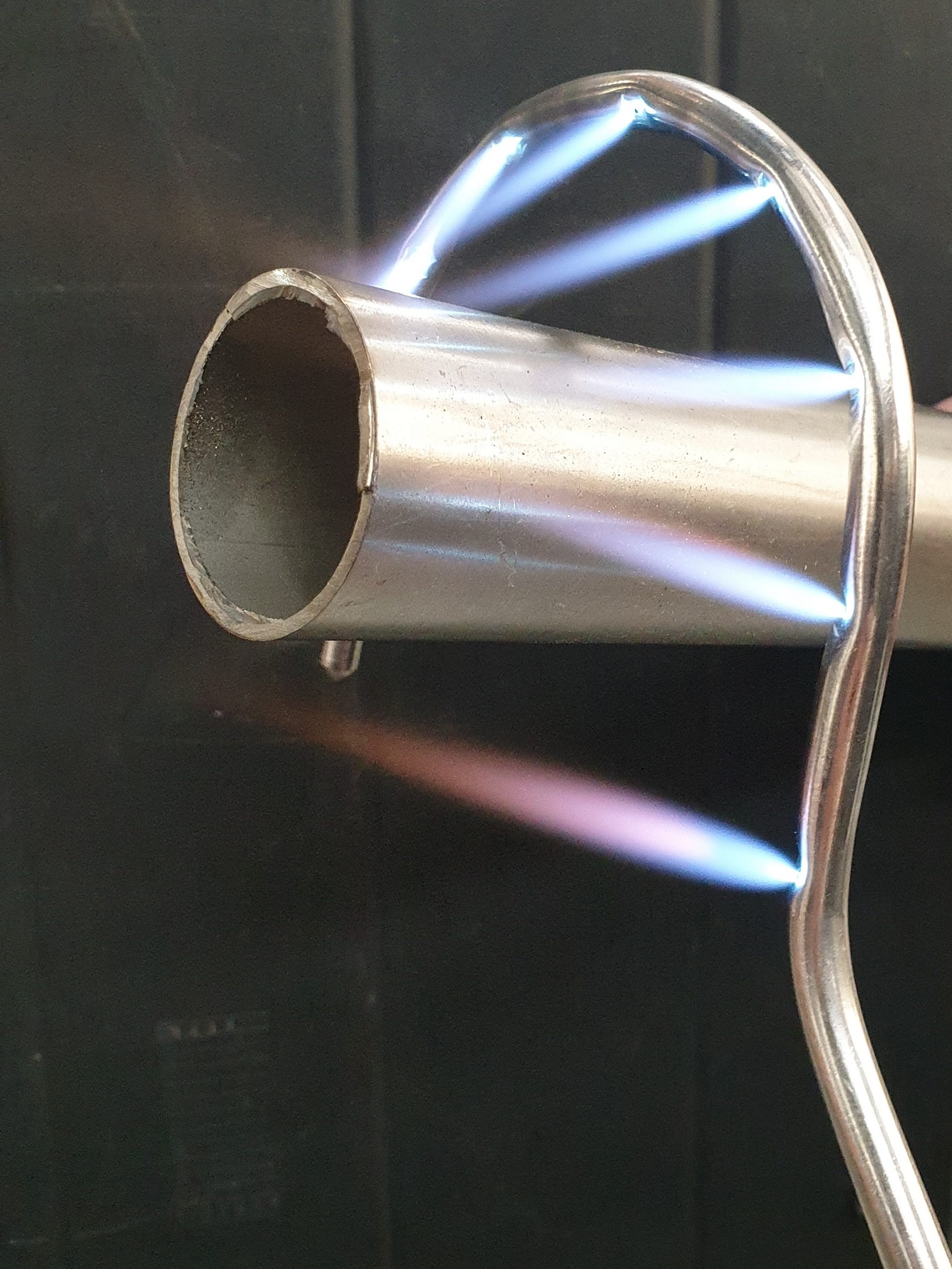

Thinner stick electrodes can also be used without flux. Oxyacetylene welding stainless steel pipe.

Working slowly around the hole, he built up filler until he closed the hole. Later i bought some of his product.

Hydrogen is preferred for underwater welding or cutting. Working slowly around the hole, he built up filler until he closed the hole.

Other welding techniques that are effective for aluminum include tig (tungsten inert gas) welding and mig (metal inert gas) welding. It is useful specifically at places.

When The Material Thickness Exceeds 15 Mm, An Extra Filler Metal, Such As A Welding Rod, Is Added.Also, you can weld other metals such as stainless steel, even if it is difficult to cut the metal unless you use high heat and pressure. Use oxweld chromaloy flux.this flux was a union carbide product and is still available.it is now sold by esab welding products,part # 724f00. Because steel melts at a temperature above 1,500 deg.c, the mixture of oxygen and acetylene is used as it is the only gas combination with enough heat to weld steel.

A Neutral Flame Setting Which Comprises 50 Percent Oxygen And 50 Percent Acetylene Is Ideal For Welding.It is useful specifically at places. Make sure there are no combustible chemicals or materials in the area where you are going to use welding oxygen. Oxyacetylene welding stainless steel pipe.

From My Research I Found That You Can Weld Stainless Steel With An Oxy Acetylene Torch, But It May Be Tricky.How is the oxy acetylene welding process? Oxygen + acetylene has a flame temp of around 3600ºc you can use a cutting torch with all 3, but oxy/propane & oxy/propylene use a different nozzle to oxy/acetylene. Oxygen + propane produces a flame temperature of around 1800⁰c.

Other Welding Techniques That Are Effective For Aluminum Include Tig (Tungsten Inert Gas) Welding And Mig (Metal Inert Gas) Welding.Clearly say your purpose because sometimes the cylinders need an acetylene test. The only real downside to using oxy/propane is that it can't be used for actual welding. Filler should be kept on the outer edge of the weld letting be 'drawn in'.

He Scrubbed It With Sandpaper, And Picked Up An Oxy Acetylene Torch.It can also be used to solder various metals together. Barb wire is better steel and makes ok filler. Working slowly around the hole, he built up filler until he closed the hole.

Belum ada Komentar untuk "Can You Weld With Oxy Acetylene"

Posting Komentar